Technical

Rhinox-Wepit system – PE-RT II polyethylene production

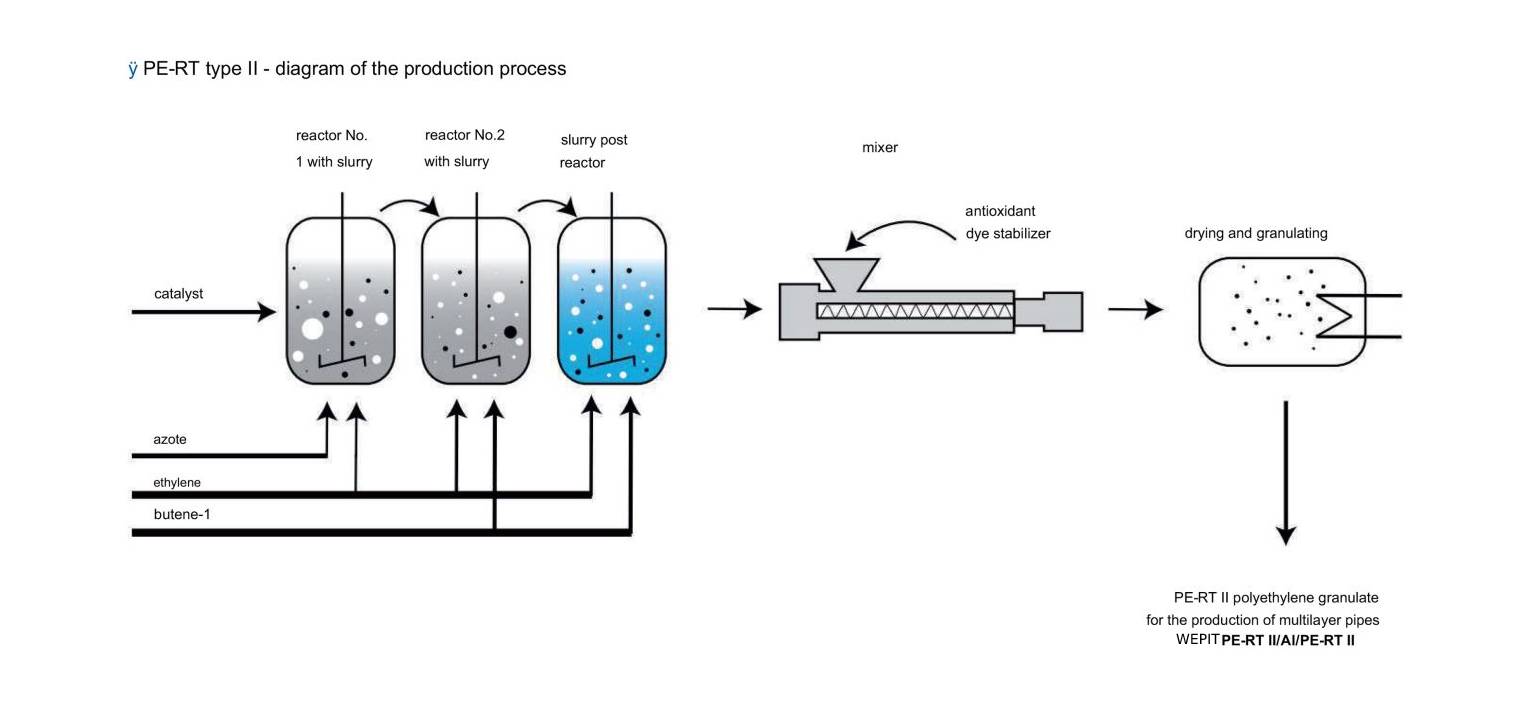

PE-RT II generation – Polyethylene of Raised Temperature type II – is an advanced type of high-density polyethylene PE-HD with increased resistance to temperature. High temperature resistance combined with strength and flexibility is obtained through technological processes of refining polyethylene – generally referred to as polymerization.

In simple terms, the upgrading processes take place in three interconnected flow reactors with complete mixing, relatively mild conditions at a temperature of 80°C and a pressure of 1 bar, in which the polymerization processes take place.

Reactor No. 1 – contains a suspension consisting of pure ethylene, a catalyst, the whole is mixed in a nitrogen shield, partially polymerized polyethylene is formed PE-RT type II – diagram of the production process

Reactor No. 2 – ethylene and butene-1 are added to the suspension of partially polymerized polyethylene from Reactor No. 1, the whole is mixed

Post-reactor – to the suspension of partially polymerized polyethylene from

Reactor No. 2, ethylene and butene-1 are added, the whole thing is mixed until a uniform structure is obtained in the postreactor, the process of polymerization of ethylene residues also takes place

Then, in the drying process with hot nitrogen, the starting products appear, a polymer in the form of a powder, which, together with admixtures, i.e. stabilizer, dye, antioxidant, is mixed and goes to the granulator. The final product is PE-RT II polyethylene granulate with a strong network entanglement structure.

The spatial structure of PE-RT II polyethylene is similar to wool, in which individual elements: threads, molecules are intertwined. The main chains of molecules have side branches, and the longer these branches, the more entangled they are. It can be said that PE-RT II is geometrically cross-linked already during its production process

Rhinox-Wepit system – construction of PE-RT II/Al/PE-RT II multilayer pipes

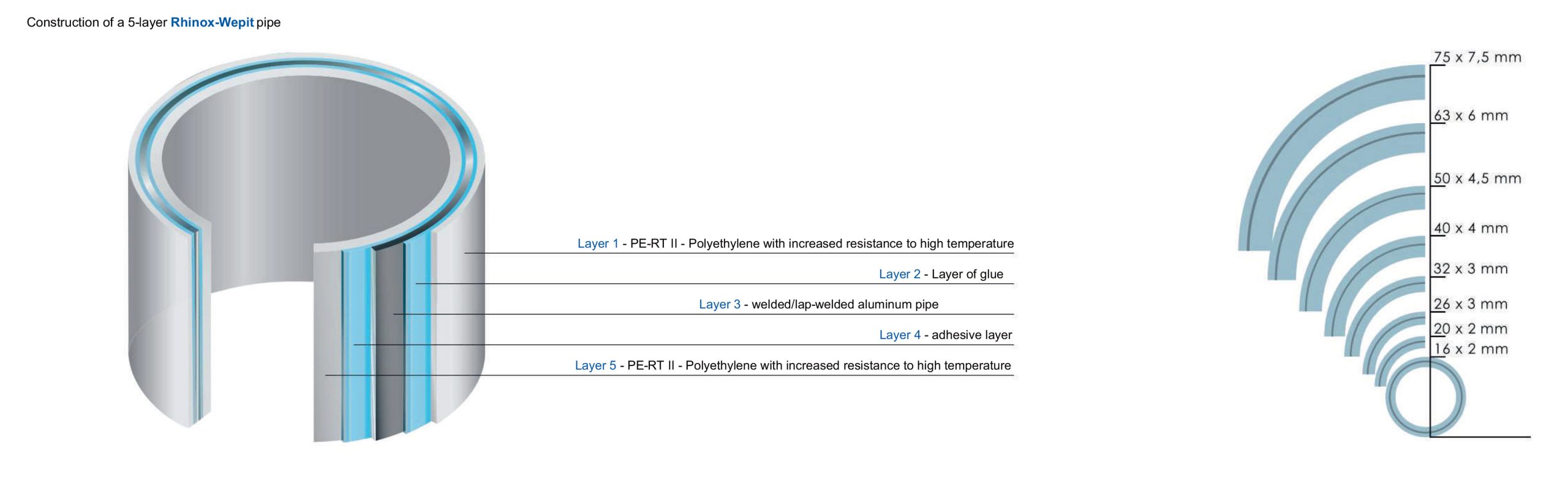

Rhinox Wepit pipes in the full diameter range of 16-75 mm are made of 5 layers. (fig.2)

The production process takes place without any chemical reactions and without any temperature fluctuations, all layers are created almost simultaneously, which results in a very complex product. The inner and outer layers are made of refined and high-quality PE-RT polyethylene of the 2nd generation (polyethylene acetate copolymer) with increased resistance to high temperatures compared to PEpolyethylene. The base of PE-RT II is polyethylene with a high density of PE-HD of 960 kg/m3, it is subjected to a special treatment. This material has longer side bonds giving it exceptional heat and pressure stability.

In terms of the properties of PERT II generation, it is a combination of the features of cross-linked polyethylene PEX and low-density polyethylene PE-LD: on the one hand, it has high strength, and on the other, exceptional flexibility. The middle layer is aluminum welded with an ultrasound or laser overlap, the technique used is strictly protected by a patent.

The thickness of the aluminum layer is variable and increases with the diameter of the pipe, so that it always maintains optimal flexibility and pressure resistance. The aluminum layer guarantees complete impermeability of oxygen to the inside of the pipe. The individual layers are joined together with a special glue of very high quality.

Wepit pipes are one of the few multilayer pipes available on the market, which are characterized by large wall thicknesses, especially in the diameter range of 40-75 mm. This involves the use of solid thicknesses of polyethylene layers and an aluminum layer. The wall thicknesses of the Wepit pipe are shown in the figure.