Best Brass Press Fitting for Secure & Durable Connections

RHINOX-WEPIT BRASS PRESS FITTNGS

Rhinox press fittings are intended to be utilised as a press fit system without the need for hot works when used with Rhinox Multilayer Composite Pipe. The stainless steel sleeve that holds the pipe to the fitting’s core is compressed by the Press Jaw, which is designed specifically for each diameter of fittings. The fitting creates a joint with maximal strength and durability after pressing.

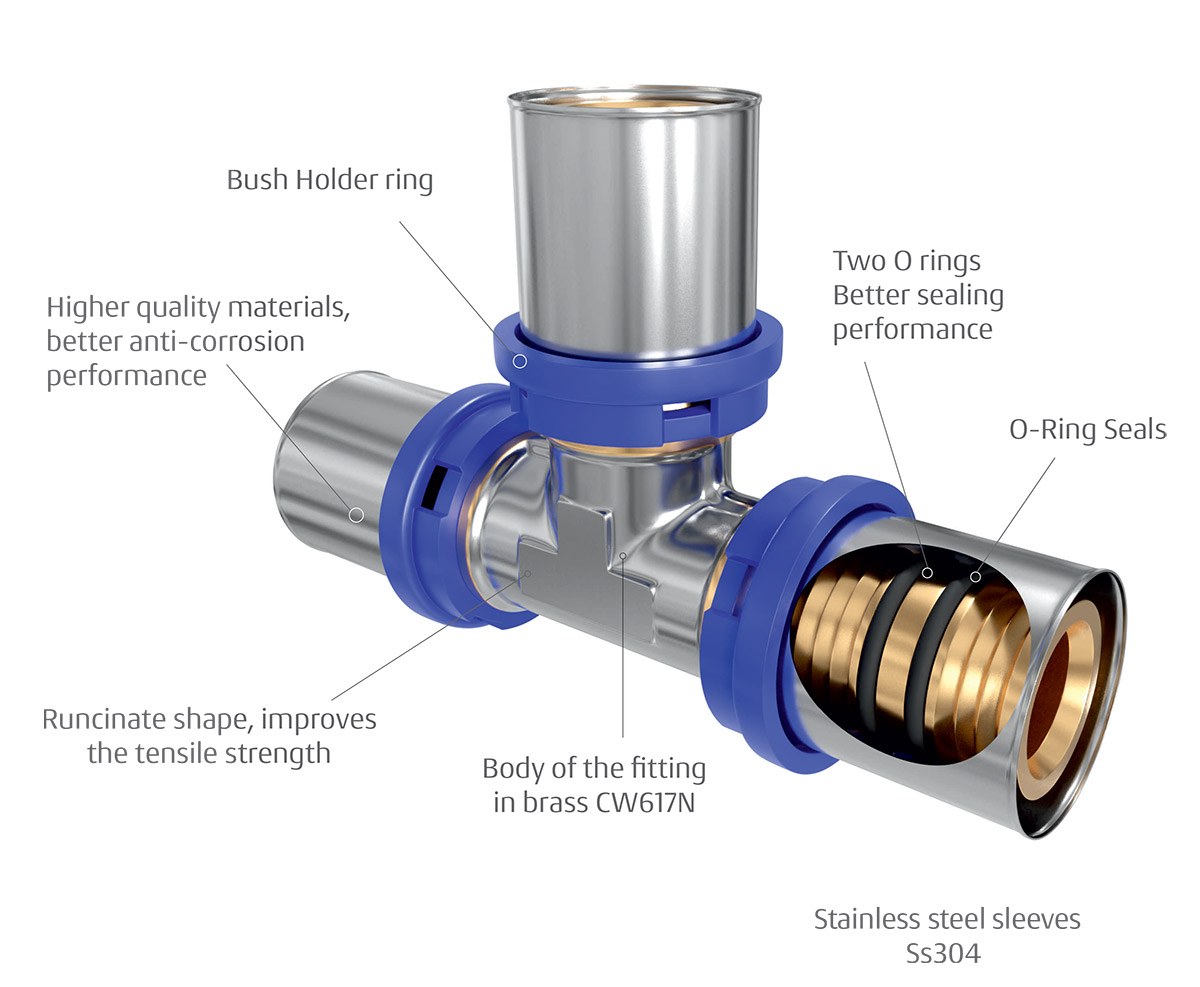

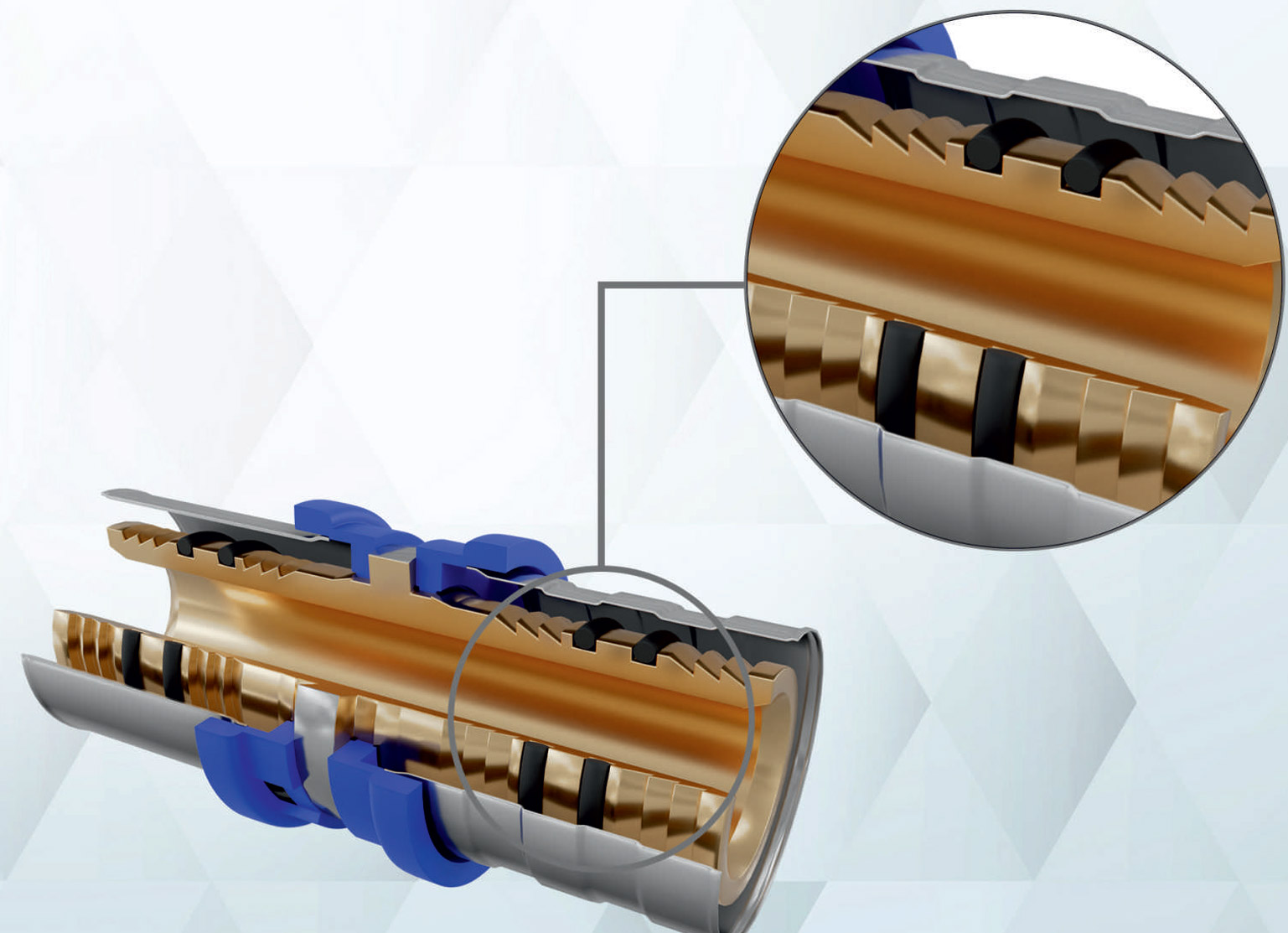

Body ofthe fitting in brass CW617N

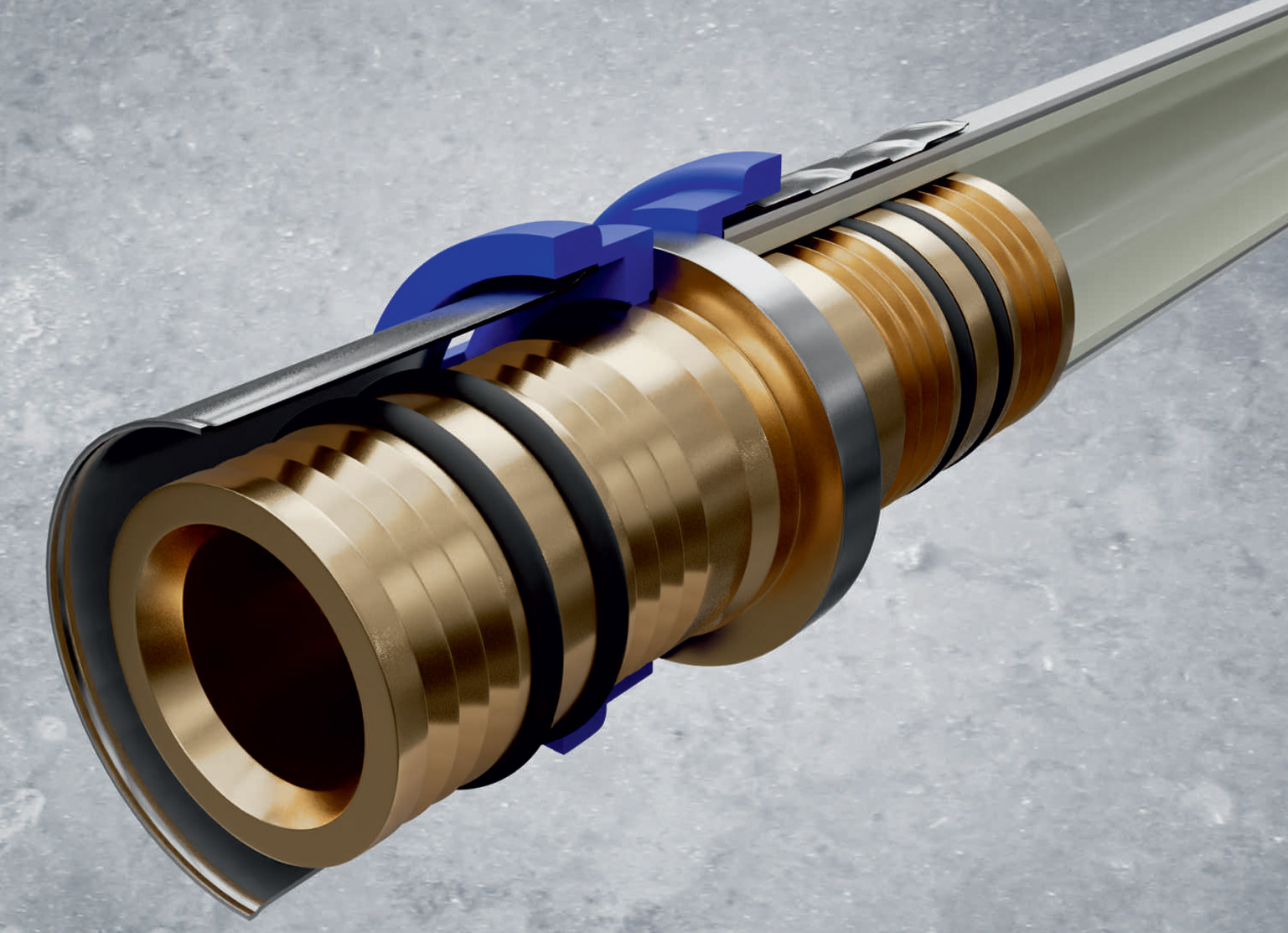

The Rhinox range of fittings are constructed with a brass nickel plated body (nickel plating is only on surfaces not in contact with the carried fluid). The body of the fitting is made up of a part that remains visible and another part that enters the tube and is called the hose holder. The latter has a special anti-slipping sawtooth profile that houses two orings which guarantee the hydraulic seal.

O-Rings Seals

Every end of the fitting that enters the pipe has two pre-lubricated orings in EPDM that guarantee the waterproof sealing of the fitting and enable it to compensate for the different expansion rates of the materials that make up the system. In case of incomplete or incorrect pressing, during system testing the fitting leaks visibly.

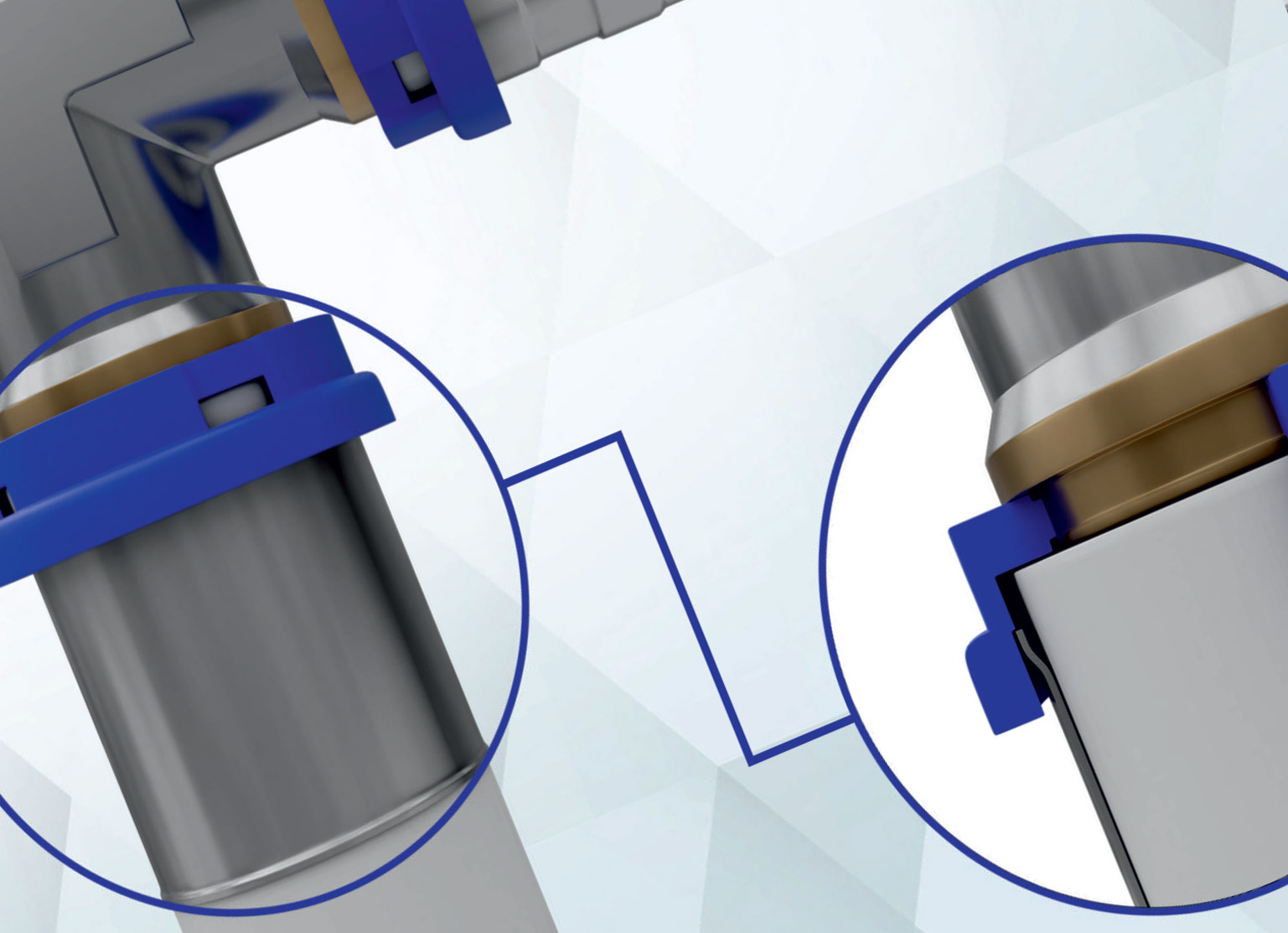

Bush Holder Ring

The blue plastic collar has sight holes which allow the installer to be sure that the pipe has been inserted fully into the fitting before pressing

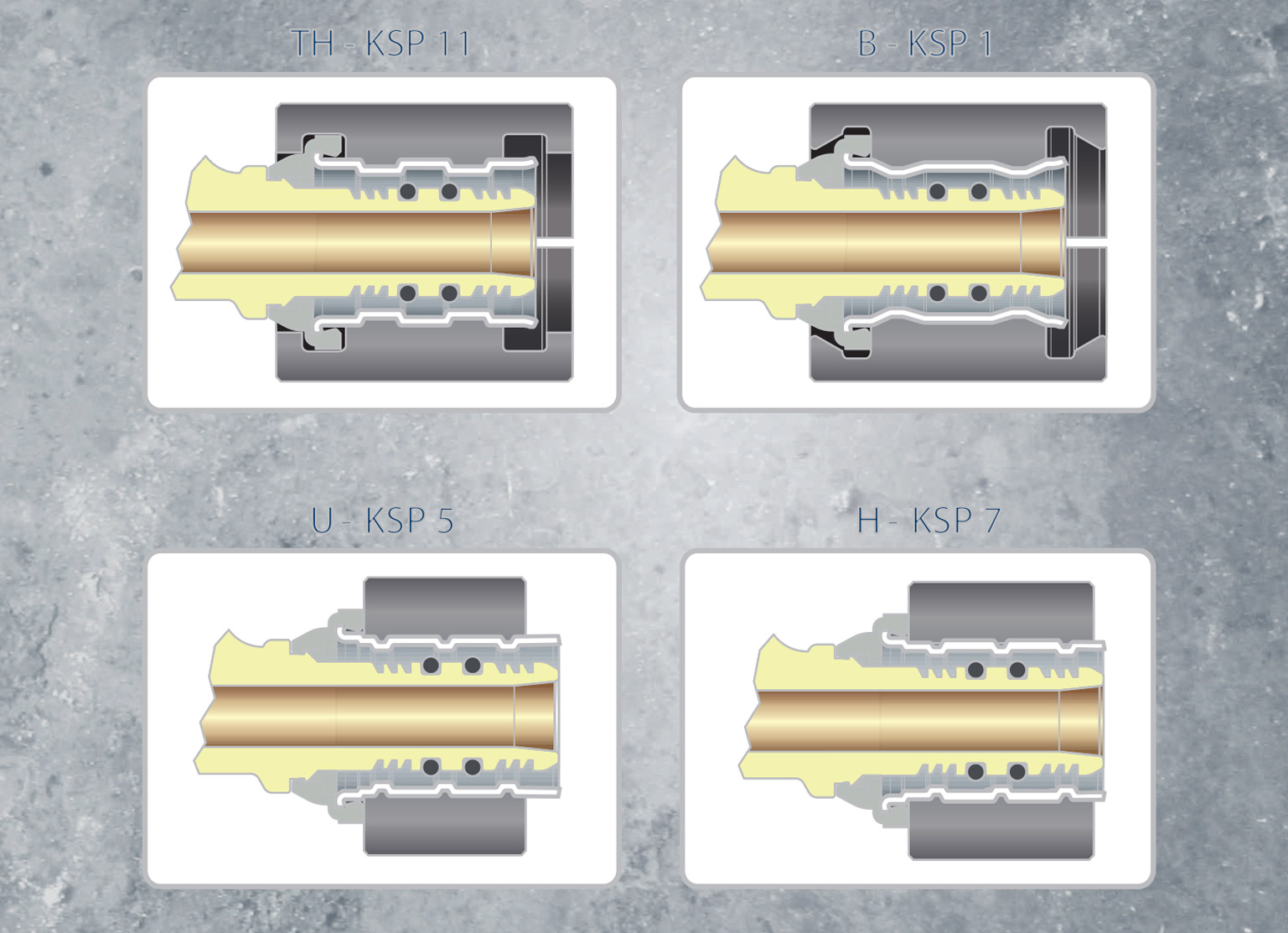

Stainless Steel Sleeve

AISI 304 stainless steel marked with the diameter, the thickness of the corresponding pipe and the pressing profile U, H, TH. It is produced by a drawing process, thereby ensuring a constant hardness of ~ 160 Hv, for uniform and safe pressing.

TECHNICAL FEATURES OF

RHINOX-WEPIT SYSTEM

OPTIMUM FLOW

Reliability is an essential aspect that makes sure lifetime performance. The quality & performance installation is defined by reducing pressure loss to a minimum. The products are curated specially to deliver appropriate flow performance, The Rhinox-Wepit with larger inner bore. These are relevant for smaller pipe diameters where the impact of inner bore on pressure loss is the most. Your consumers will indeed make the most out of this prolific & wonderful fittings range.

OPTIMUM FLOW

Reliability is an essential aspect that makes sure lifetime performance. The quality & performance installation is defined by reducing pressure loss to a minimum. The products are curated specially to deliver appropriate flow performance, The Rhinox-Wepit with larger inner bore. These are relevant for smaller pipe diameters where the impact of inner bore on pressure loss is the most. Your consumers will indeed make the most out of this prolific & wonderful fittings range.

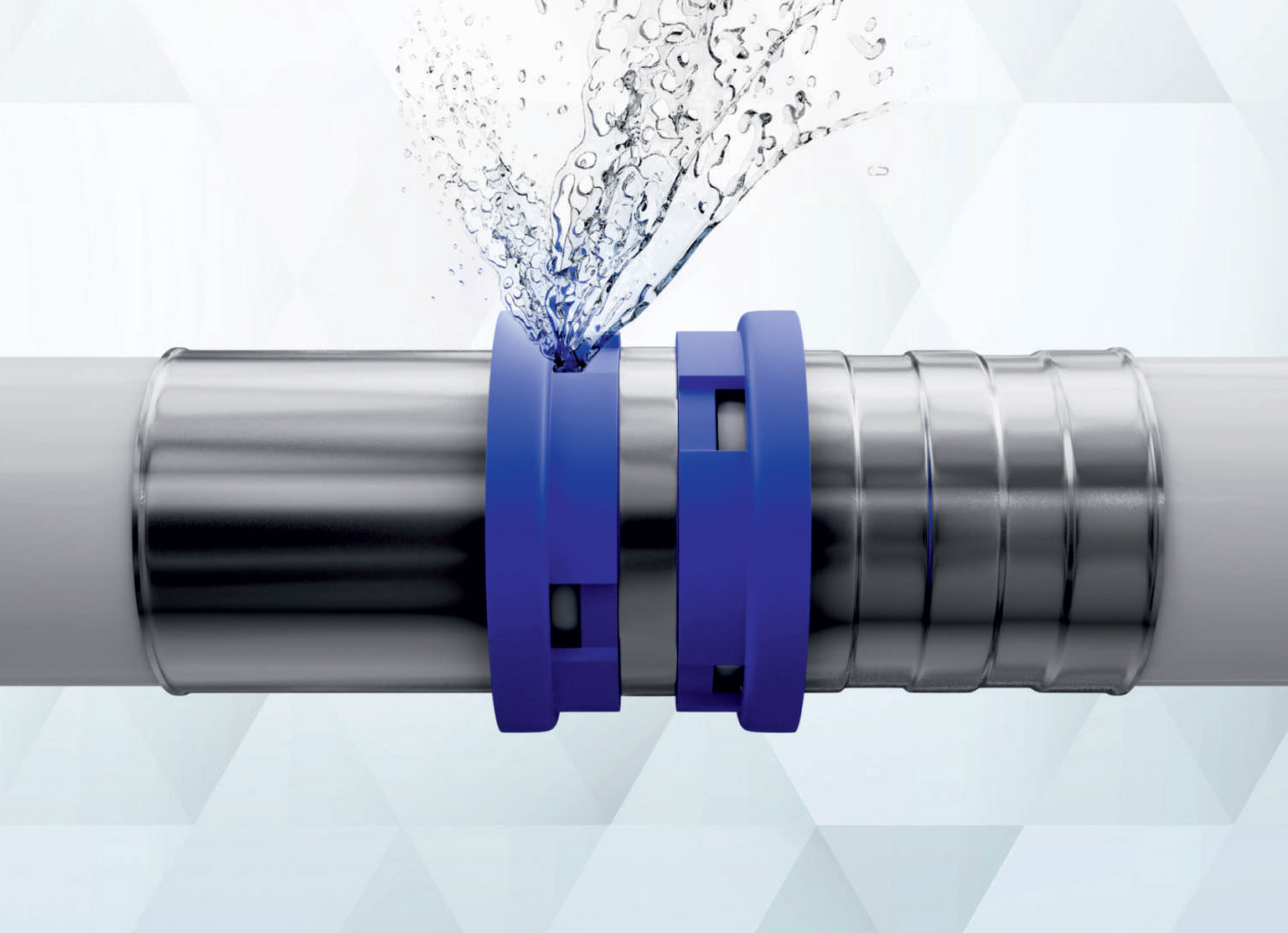

LEAKY IF UNPRESSED

When the pressure test is put into action with water, the quality of defined leak reassures that the faulty unpressed connection is clearly visible with the naked eye to make it easier for the installer to check for leakages while pressure test is being performed.

EASY AND RELIABLE INSTALLATION

Special Sawtooth and retaining rings on the brass fittings achieve a high level of fitting retaining force in the pipe and prevent the fitting slipping out of the pipe during installation. The pipe system is therefore easy to install, align and then press

INSERTION DEPTH CONTROL

The insertion depth remains visible at all times. This ensures that the pipe is correctly pushed onto the fitting during installation and can then be correctly pressed. The piping system can therefore be pre-mounted. When the system is ready to be pressed, each connection can be checked immediately to ensure that each pipe is in the correct position.

RESISTANTTO MECHANICALSTRESS

Every day it can happen that the fitting is exposed to sudden mechanical loads. That’s why we made the new design of heavy brass fittings take more load and shock-resistant, proving great stability under heavy mechanical forces.