Multi Layer Composite Pipes with Advanced PEX-B Silane Cross-Linking

Rhinox Multi Layer Composite Pipes Offers Superior Performance

Our Rhinox-Wepit PERT-II pipes are engineered for fast and flexible installation, offering superior corrosion resistance and protection against tuberculation and deposits. Designed to perform in extreme conditions, they remain intact even in sub-zero temperatures—no freezing, no bursting.

Thanks to their low noise transmission and smooth inner surface, PERT-II pipes ensure optimal water flow, reduced pressure loss, and minimal buildup. Compatible with the same trusted connection systems used in PEX, they deliver long-term, leak-free performance for both residential and commercial water supply networks.

LONG LIFE

If the pipe is used according to the specified working pressure and temperature, it will have a guaranteed working life of at least 50 years.

RESISTANT TO TEMPERATURE AND PRESSURE

The working temperature can be up to 95°C, and the maximum working pressure 10 bar.

RESISTANCE TO ABRASION

Rhinox Wepit has a high resistance to abrasion, even with water containing high levels of impurities and high-speed flow

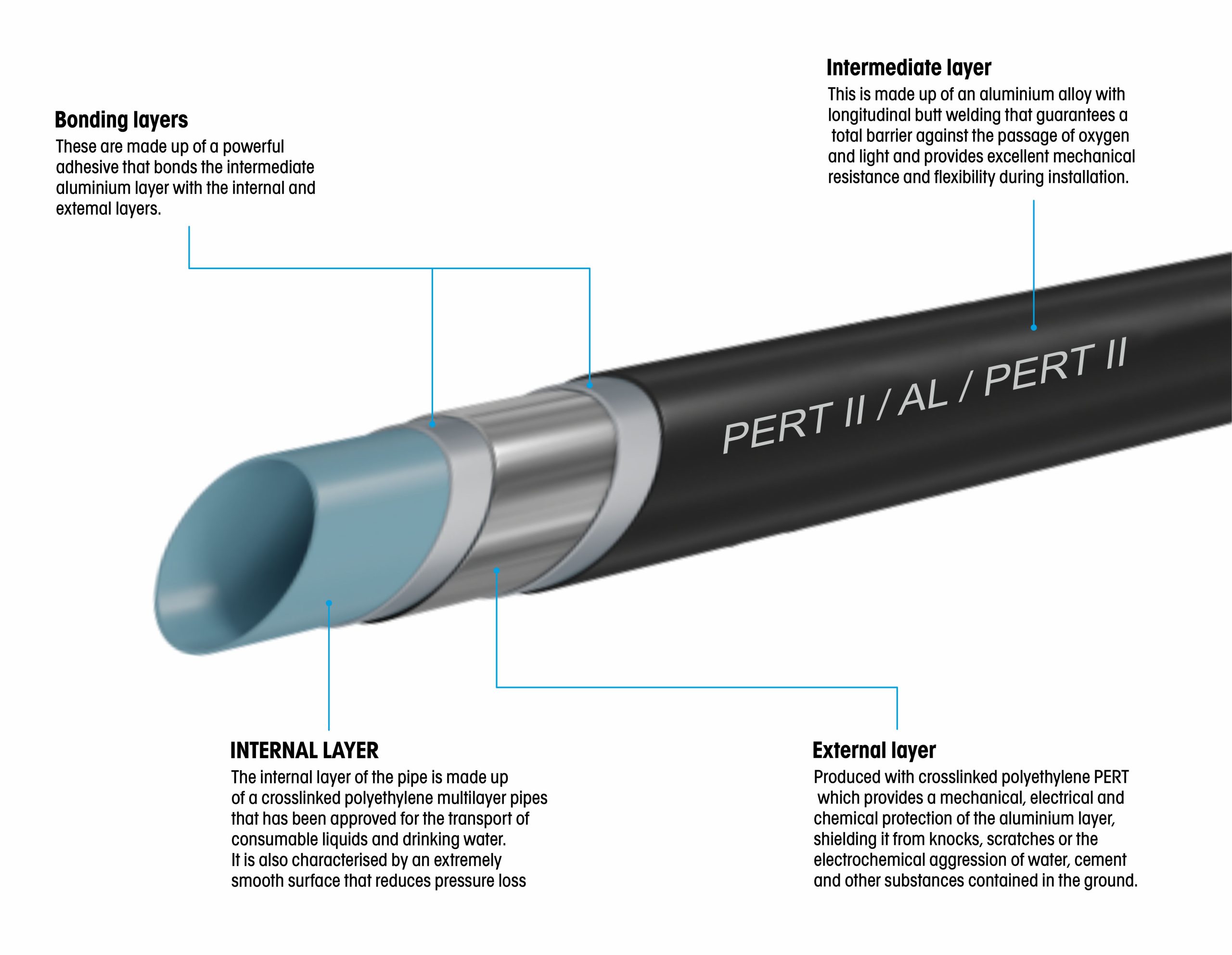

MINIMUM LINEAR EXPANSION

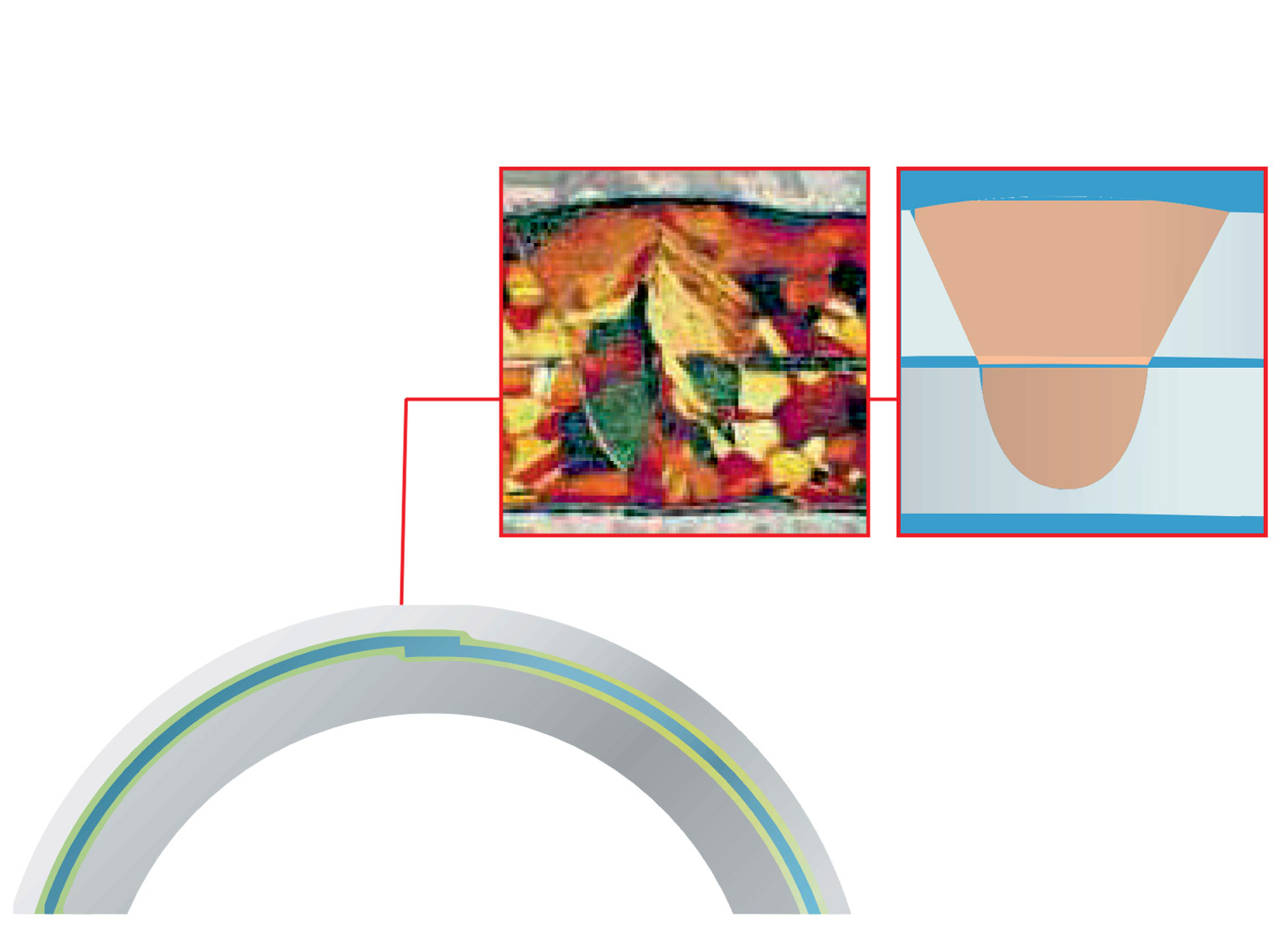

The aluminium layer in the Rhinox pipe means that it has a coefficient of expansion comparable to that of copper and 8 times less than an ordinary plastic

pipe. Its coefficient of expansion is 0.025 mm/mK.

OXYGEN AND LIGHT BARRIER

The aluminium layer blocks the passage of oxygen, water vapour and any other gas, therefore avoiding the formation of corrosion in the circuits. Aluminium is also a fully-effective barrier against UV radiation.

CORROSION RESISTANCE

The polyethylene internal and external layers and the fittings provided with a dielectric barrier protect the aluminium against any type of chemical, electromagnetic and natural corrosion.

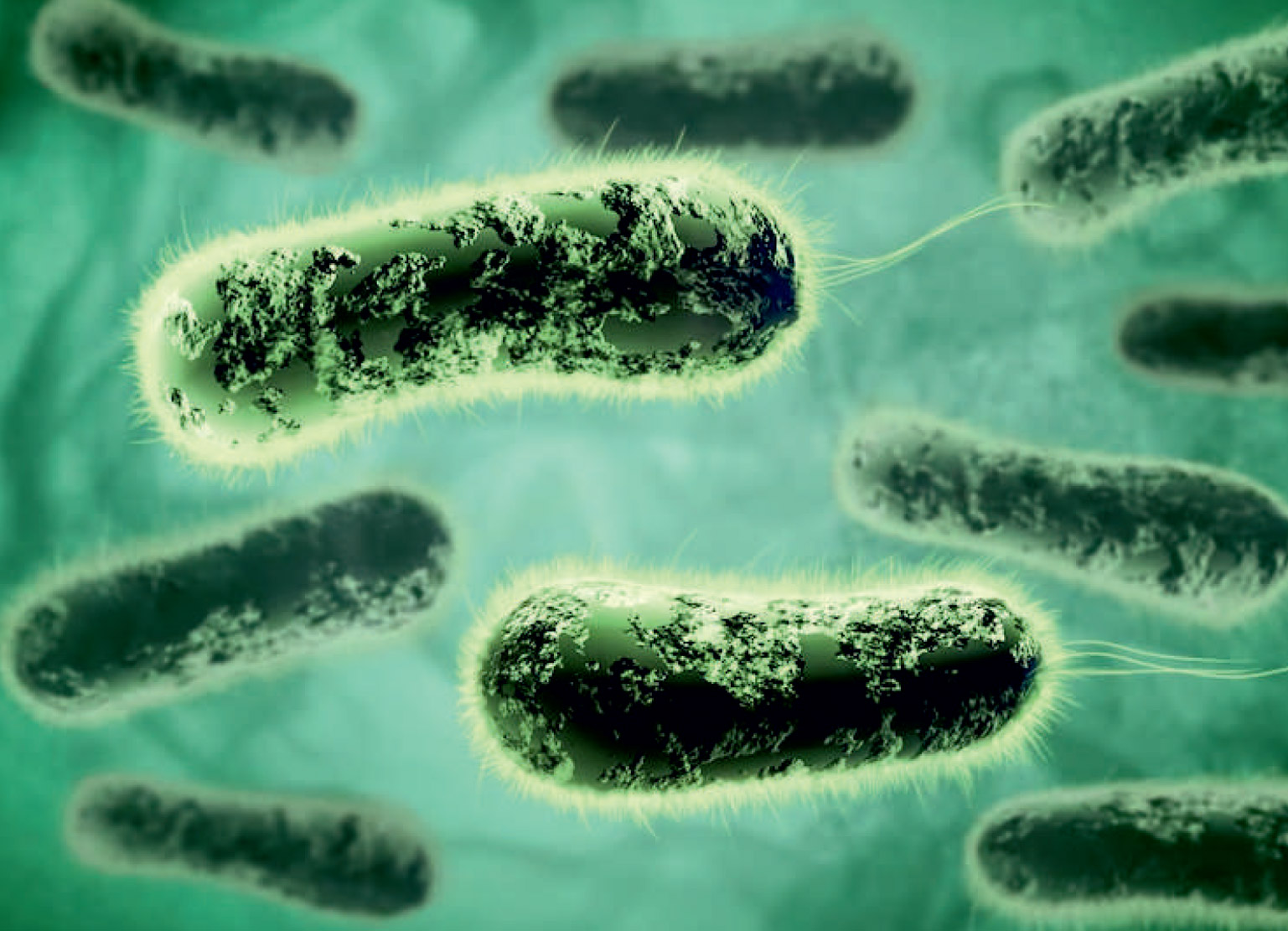

HYGIENIC AND NON TOXICOLOGICALY

Rhinox-wepit multilayered pipes have been tested at a number of laboratories throughout the world and are approved for tap water distribution, i.e. the pipes release neither taste, odour nor unhealthy substances regardless of water quality.

CHEMICAL RESISTANCE

The Rhinox-wepit multilayered pipe has a very high resistance to chemicals. Building materials such as concrete, mortar, plaster, etc. do not affect the pipes negatively. Tape, paint or sealing compounds containing softening agent must not be used directly on the pipe.

LOW LOAD LOSSES

The internal polyethylene surface has a surface finish that can ensure significant reductions in load losses compared to classic metal pipes; furthermore, the absence of lime deposits or other scaling ensures a flow rate that remains constant over time.

TECHNICAL FEATURES OF

RHINOX-WEPIT SYSTEM

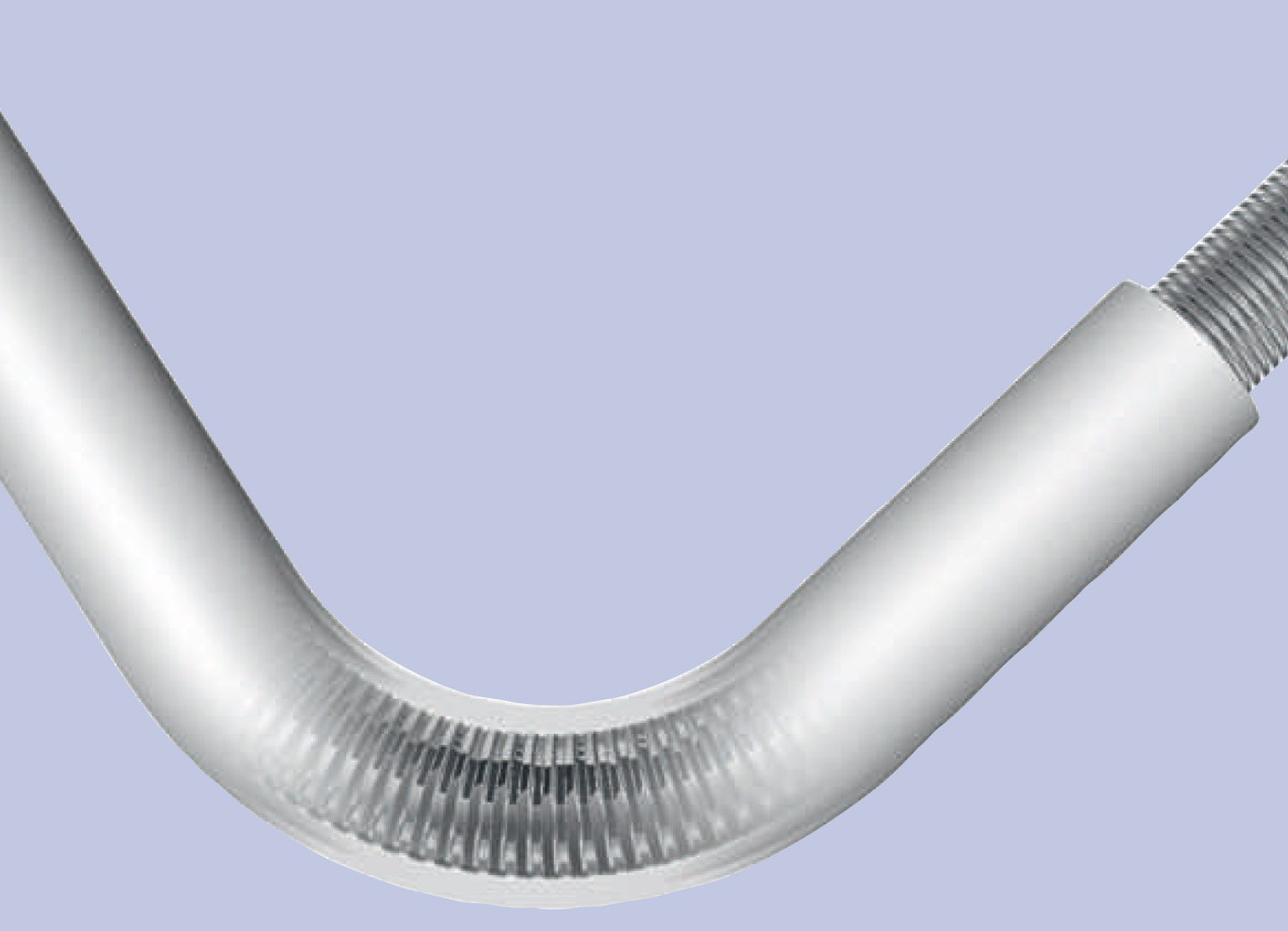

TIME AND MONEY SAVING INSTALLATIONS

Thanks to their excellent mechanical characteristics the Wepit multilayer pipes can be bent instead of employing fittings thus obtaining significant advantages from an economical point of view.

FIRE RESISTANCE

The installation of a system must always be performed in compliance with local and national standards and regulations, observing any fire protection provisions in force that may vary from one country to another.

LEGIONELLA AND TREATMENTS

Compared to metal pipes, Wepit multilayer pipes have a greater resistance to chemical compounds and may undergo treatments (eg. superchlorination shock) for several years without being damaged.

ACCESSORIES

A wide range of accessories and special components complete the system in order to meet all system requirements.

Modular manifolds with and without interception valves, coplanar manifolds, manifolds with shut-off valves, in-wall ball valves, fixing plates for sanitary appliances and many other items…

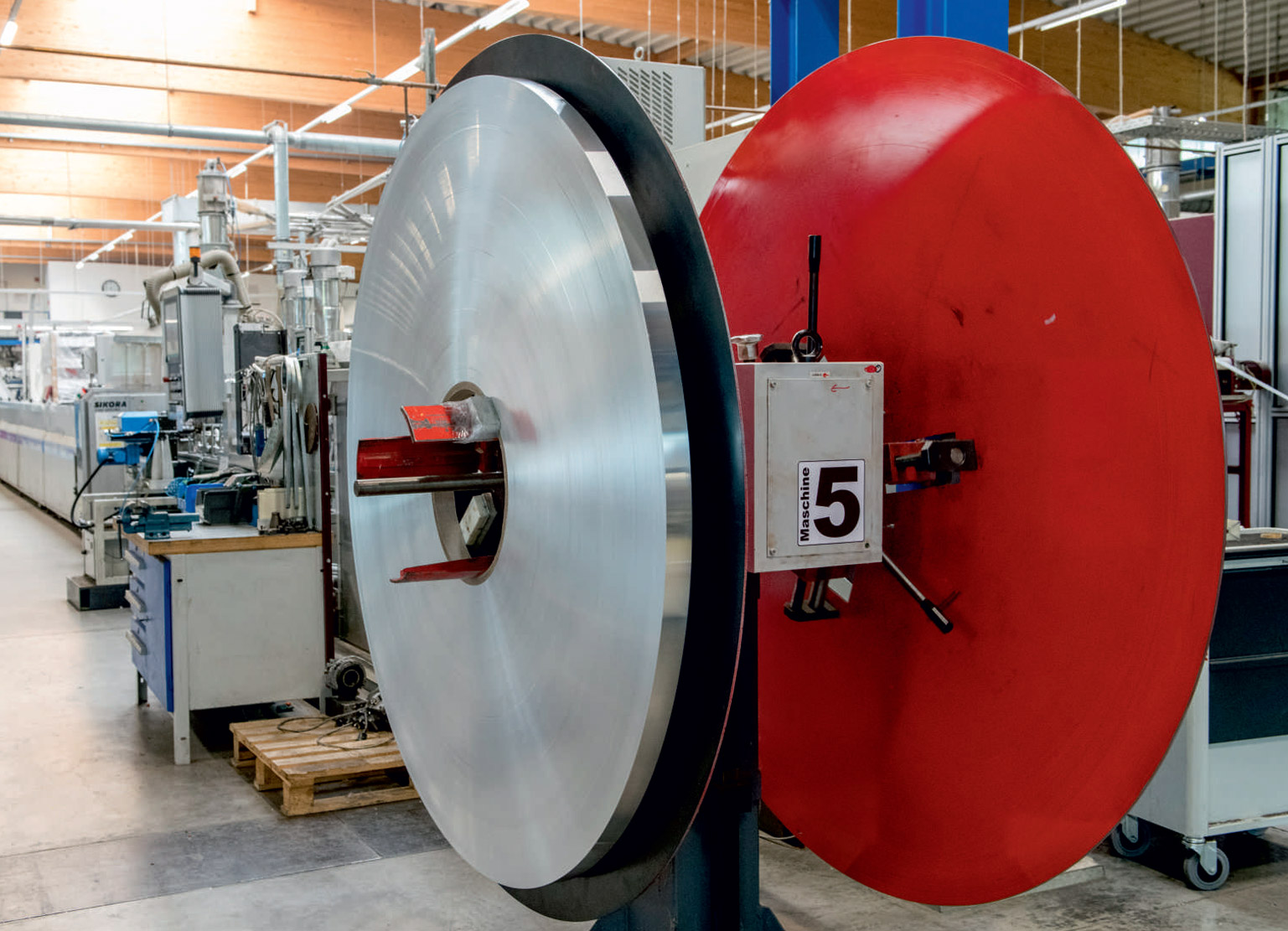

ALUMINIUM

There are different methods for the production of multilayer pipes and they differ mainly in the technology used in forming the aluminium pipe. It can be formed by overlapping, overlapping and welding, or by butt connection and welding.

Chosen by Wepit in that it guarantees a uniform thickness across the entire circumference, greater resistance to pressure and bending, uniform mechanical characteristics, greater adhesion values with the bonding layers and a total barrier to oxygen.

LASER WELDING ALUMINIUM

One of our outstanding innovation is the over lapped. laser welded multilayer pipe. Ultimate precision and strength for optimum quality.